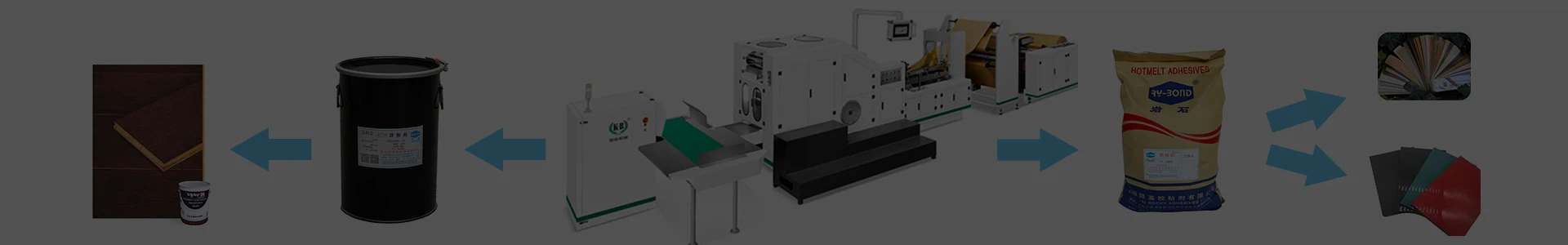

Laser Edge Banding Back Coater

Laser Edge Banding Back Coater

It consists of operation screen and electric control, screw type glue machine, scraper device, cooling system, double-flat sealing strip device, automatic sealing strip receiving device, automatic sealing strip joint detecting device and automatic sealing strip receiving device.

The laser edge banding back coating machine consists of: operation screen and electric control, screw type glue machine, scraper device, cooling system, double-flat edge banding device, automatic edge banding device, automatic edge banding joint detection device, and automatic edge banding device.

Technical Parameters

External Dimensions

7000x1025x1600mm(L*W*H)

Line Speed

3-60M/min

Gluing Width

10-80mm

Total Power

5kw

Total weight

1.5t

Performance Characteristics

1. Operation screen and electric control

With the function of internet of things, cell phone or computer can remotely check the production status and output of the equipment and set the heating temperature.

The whole line has the function of one-key operation, which is convenient and quick to operate. The thickness of sealing strip gluing is automatically controlled by PLC according to the change of gluing speed and width to keep it constant.

2. Screw type gluing machine

Adopting 1.5kw self-service motor directly connected with single screw to dissolve glue; fast dissolving, no yellowing of glue, easy to change color, saving glue and time.

3. Squeegee device

Adopting imported steel, even glue application, the opening and closing of the glue application port has a scale, the whole scraper has up and down and left and right micro-adjustment movement function, precise glue application control.

4. Cooling system

Equipped with air-cooled and water-cooled cooling methods to improve cooling efficiency.

5. Double flat sealing strip device

Reserve one more working station for putting sealing strip to improve working efficiency. With tension function.

6. Automatic sealing strip connecting device

Adopting infrared probe detection, it can realize automatic splicing of two rolls of sealing strips and continuous production without stopping.

7. Automatic detection device for edge band joints

Adopting infrared probe to detect the position of joints and automatically control the lifting and resetting of gluing head to realize non-stop continuous production.

8. Automatic sealing strip rewinding device

Servo motor torque mode automatic winding, automatic detection of joints, automatic cutting and winding.

How To Cooperate With Us ?

Demand Confirmation

Please submit your requirements and project details through the website or directly contact us. This step helps in understanding your needs.

Consultation and Quotation

Our team provides a detailed consultation, discussing the project scope, materials, machinery, and customization options.

Supply Chain Matching

Identify suitable partners from our supply chain network. Then, based on your product requirements and budget, select appropriate suppliers. Subsequently, our partners will deliver high-quality products and services within specified timelines.

After-Sales Support

Our after-sales team provides support for installation, troubleshooting, and any other technical assistance required.

Hot Tags: laser edge banding back coater, China laser edge banding back coater manufacturers, suppliers, factory, BOPP Shrink Film, PVC edge banding, Edge banding thickness gauge, Hot Melt Adhesives for Medical Dialysis Paper, Spring Bag Glue, Automatic Feeding Edge Banding Machine

Previous

wood profile wrappingYou Might Also Like

Send Inquiry