The development direction of diapers

Thin - diapers will continue the trend of thin development, this is the demand of mothers and manufacturers of cost compression results. Loose diapers cause a lot of inconvenience to mothers and babies. For manufacturers, loose diapers undoubtedly occupy a larger space and consume more costs in consumables, transportation and other aspects. Manufacturers will gradually increase SAP content and reduce the proportion of fluff to meet consumers' demands for increasing the liquid absorption of diapers, and objectively make diapers develop in the direction of thin shape, such as the super thin diaper series of Dahuan.

Skin care - While diapers provide convenience for mothers and babies, they also have hidden disadvantages. Diaper rash is one of the unavoidable problems. Although there are factors of individual differences, the incidence rate of up to 35% (" Non-woven World ", February - March 2000) has pushed this problem to the forefront. Using diapers is not only convenient, but also comprehensive care. Skin care is mother's desire, but also the direction of the market.

Environmental protection - The layer of nappies that doesn't break down easily is a form of "white pollution," and environmental activists are also attacking this. With the development of society, the importance of environmental protection has become increasingly prominent and been paid attention to. The production of environment-friendly diapers is not so much the product of pressure, but rather an inevitability.

Synthetic core - core is the most important functional layer of diapers, the production process is complex, and the mixing of polymer and fluff directly affects the performance of the product. The core of the future is toward composite molding, which is made of idealized dust-free paper and contains a uniform mix of SAP and fluff, enhancing better characteristics and performance in terms of liquid control performance. Core processing is divided from the entire production process, and only the selected functional layer can be synthesized in the production of diapers, which not only simplifies the production process, ensures the integrity and softness of diapers, but also effectively controls the cost.

Training pants/pants - Training pants first appeared in Europe and the United States in the 1990s. A large area of the waist and leg circumference of the material is non-woven fabric and rubber, not only better elasticity, more comfortable fit, and does not bring expensive production costs. In Japan, training pants are not far from adhesive diapers. In China, the mother gives the child the excrement and urine very early, and the posture is against nature, often cause the child crying and noisy, leading to psychological risks, let the child wear training pants is an effective way to cultivate the child's toilet habit, use the child is willing to grow into a big child and love to imitate the psychology, to put on the child's self-help diaper - training pants, not only to ensure safety, but also to maintain the child's self-esteem, Good for children's physical and mental health.

Stretchy fitting ---- Rigid tight diapers are not conducive to Baby exercise. The development and design of more elastic materials make the diaper elastic and tight, so that the baby can do climbing, walking and other sports more freely. These elastic materials and designs include elastic waistlines, elastic large ear stickers and more.

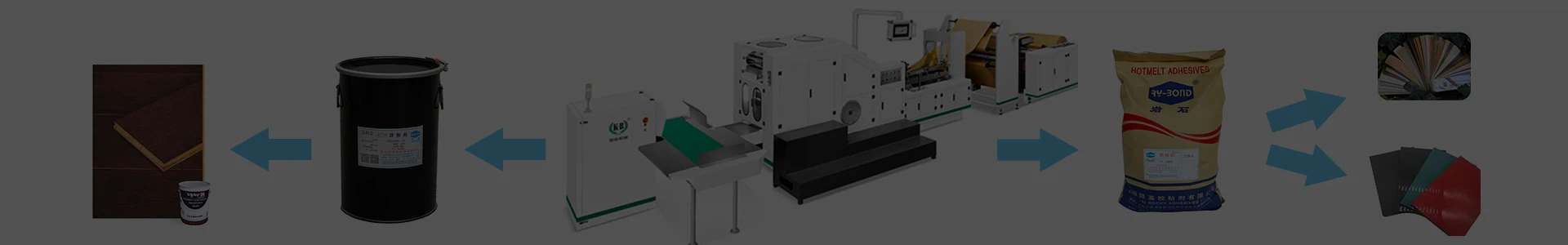

Soft ---- Thin design can play a role in making diapers soft, but in order to further improve the baby's skin comfort, it is necessary to choose super soft surface fabric, but also need to screen the softness of other materials, including absorbent paper, bottom film and hot melt adhesive.