We often hear a lot of consumers like this complaint: "I bought a new kitchen cabinet not long, the door edge is cracked and warped, and a pungent smell." I'm afraid this headache has always been a problem for the vast majority of consumers. This involves a very important link in the manufacturing of these cabinets in the factory, that is the edge link.

"Cabinet, wardrobe, bathroom cabinet quality is not good, edge quality is absolutely can not be ignored details", this is the view of many industry insiders, but also many consumers at present to choose and buy standards.

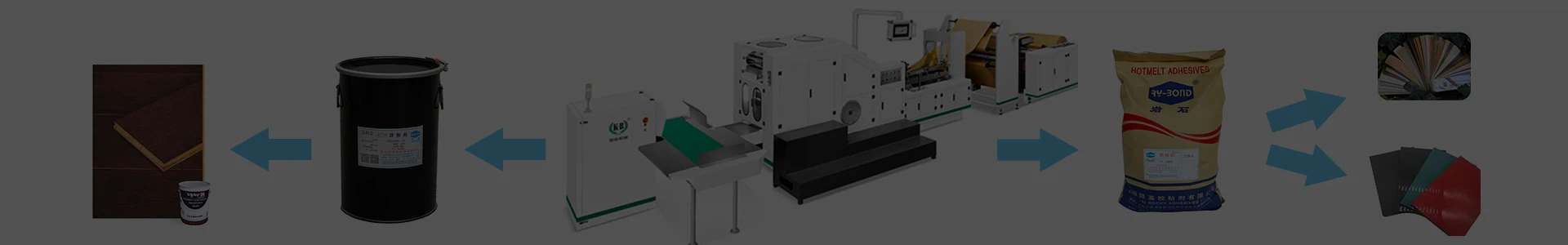

The edge sealing link as a plate furniture processing process should be the most important and the most rare link, no correct or low quality edge, will affect the final use of a furniture effect, the importance of the edge can be imagined. For furniture manufacturers, in recent years, there has been a rush to upgrade their edging machines to improve the quality of the final product. There is no doubt that having a high-precision, multifunctional and industrial edge banding machine has become the breaking demand of many advanced plate processing enterprises. In Inspur, whether the enterprise really understand the banding machine, may need to put a question mark.

Structure and function of edge banding machine

Edge banding machine functions include: pre-milling, glue coating, head, rough repair, fine repair, scraping, polishing, slotting. Mainly used for panel furniture and wooden door production.

1. Pre-milling: The use of double milling cutter on the cutting plate saw after processing caused by corrugated marks, burr or vertical phenomenon, to modify again, in order to achieve better edge sealing effect. Make the edge strip and plate fit more closely, integrity and beauty is better. 1. Glue-coated edge sealing: through the special structure, so that the edge sealing plate and the edge sealing material double-sided glue evenly, to ensure that the adhesive force is more firm.

2. Glue-coated edge sealing: through the special structure, so that the edge sealing plate and the edge sealing material double-sided glue evenly, to ensure that the adhesive force is more firm.

3. Unified head: Through precision linear guide rail movement, the use of mold automatic tracking and high frequency high speed motor fast cutting structure, to ensure that the cutting surface smooth.

4. Rough repair/finishing: adopt automatic tracking by mold and high frequency high speed motor structure to ensure the upper and lower parts of the trimming plate smooth. It is used to repair and remove the excess edge sealing material up and down the edge sealing strip.

1) Rough repair function: rough repair knife for flat knife. In order to deal with the excess parts of the veneer trimming. Because when sealing veneer, you can not directly use the finishing knife R-shaped knife, veneer is generally 0.4mm thick, if you directly use the finishing knife, easy to cause fracture. In addition, rough repair can also be used to seal PVC, acrylic when the first flat repair process.

2) Finishing function: the finishing knife is R-shaped. Mainly used for panel furniture PVC, acrylic edge strip, with 0.8mm thick above the edge strip is preferable.

5. Scraping: used to eliminate the ripple marks caused by the cutting process of non-linear trimming, so that the upper and lower parts of the plate are more smooth and tidy.

6. Polishing: Clean the processed plate with cotton polishing wheel, and make the edge end face smoother by polishing.

7. Slotting: It is used for direct slotting of wardrobe side plate and bottom plate, so as to reduce the cutting and sawing process more convenient and quick; It can also be used for slotting of aluminum edge of door panels.