Hot Melt PUR Production Line

Hot Melt PUR Production Line

The Hot Melt PUR Production Line is an equipment system used for producing polyurethane reactive hot melt adhesives. The Hot Melt PUR Production Line includes pre-melters, reactors, transfer pumps, discharge pumps, mold temperature controllers, screen changers, vacuum pumps, sprayers, nitrogen generators, steel platforms, instruments, pipe and valve components, control systems, pre-assembly units, and ovens. These devices achieve high-quality production of PUR hot melt adhesives through precise control and efficient operation.

components of the PUR hot melt adhesive production line

1.0 MT reactor /pre-melter mixer

Capacity: 1000kg/ batch

Full volume of reactor: 1500L

Working volume: about 1000L

Heating method: oil heating, Max.300℃

Design pressure: -0.098-0.3mpa

Mixing system: 45KW motor, Double turbo-high-speed blades

Material: Stainless steel S304

Discharge melt (gear) pump

Flow rate: 50-4000L/Hr

Heating method: Jacket heating

Pump material: stainless steel

Sealing method: high temperature resistant TPFE packing seal

Motor: Power 5.5KW, variable frequency motor

Advantages: Suitable for high and low viscosity, less internal residue.

Screen changer

Used to filter molten material during the production process.

Model: single plate, single working position

Heating method: Jacket heating

mold temperature controller

For heating and cooling control, or for use with heat-conducting oil boilers.

Model: Electric heating (50KW), connect external cooling water to cool

5.5KW vacuum pump system

Up to 100Pa vacuum, special oil fog, dust filtration equipment, abandon the traditional condenser, etc., to prevent the emulsification of vacuum lubricating oil and reduce exhaust gas emissions.

Sprayer

2 pieces, 360° cleaning. Connected to the discharge pump, the solvent is circulated to the tank for cleaning the discharge line and tank. To achieve a small amount of cleaning liquid can clean the reactor and pipe purpose.

The height of the platform is about 3.6-4m, and the load is 500kg/㎡. The whole production line features:

1. Suitable for PUR high - low viscosity products;

2. The equipment is easy to clean; Very low residue control;

3. Mature technology, stable operation of equipment; Avoid product impurities, bubbles and other common problems.

4. Key equipment are all well-known brands.

Space parts list:

1, Mechanical sealing of mixer shaft:

2, Sprayer O rings: 3*

3, The blade of mixer:

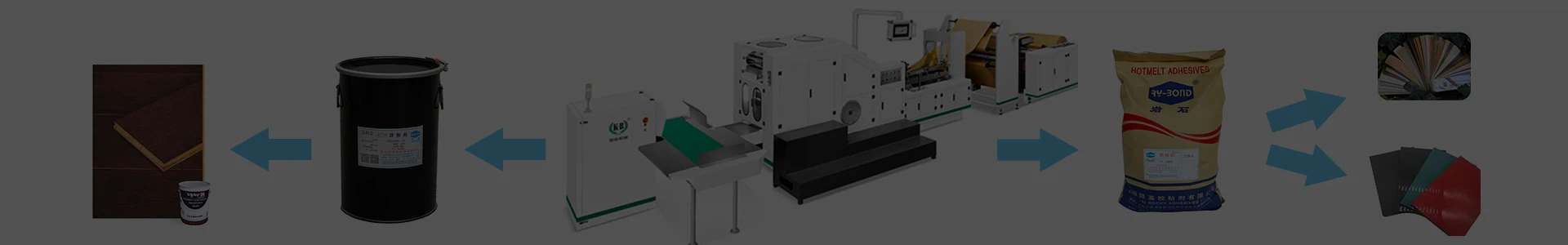

production process of PUR hotmelt adhesive

Hot Tags: hot melt pur production line, China hot melt pur production line manufacturers, suppliers, factory, Hot Melt Coating Machine, Wooden Panel Vacuum Lamination, Carton Window Patching Glue, Edge banding quality, Rubber Wood Powder, Courier Bag Seaming Glue

You Might Also Like

Send Inquiry